Powermaster Boiler / Burner Specification Data

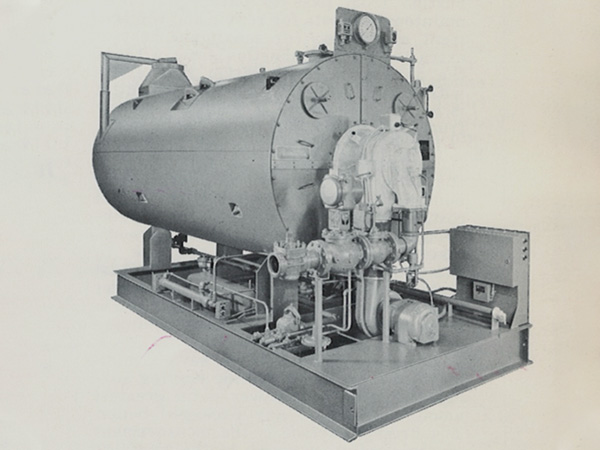

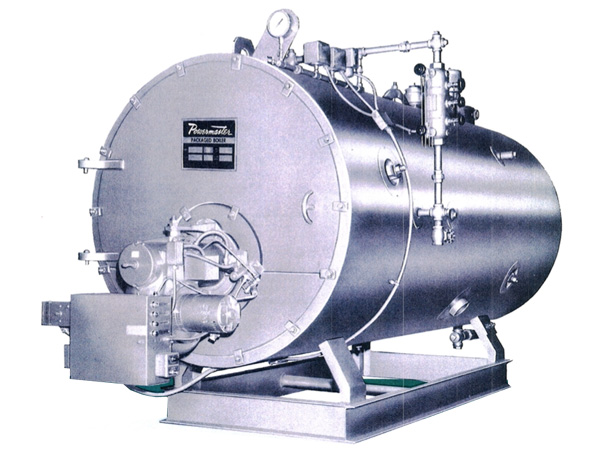

POWERMASTER MODEL 7 BOILER

Rugged Powermaster Model 7 packaged boilers are ideally suited for fully automatic forced draft operation in the 20 to 300 boiler horsepower range. They are available in either high or low pressure models for steam or hot water and for firing light oil, gas or combination gas-light oil. With dryback construction, field repair is easily made from standard refactory materials. All Powermaster packaged boilers provide efficient and economical performance.

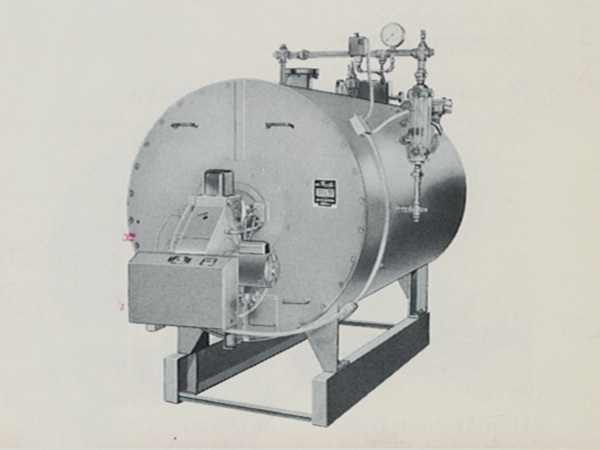

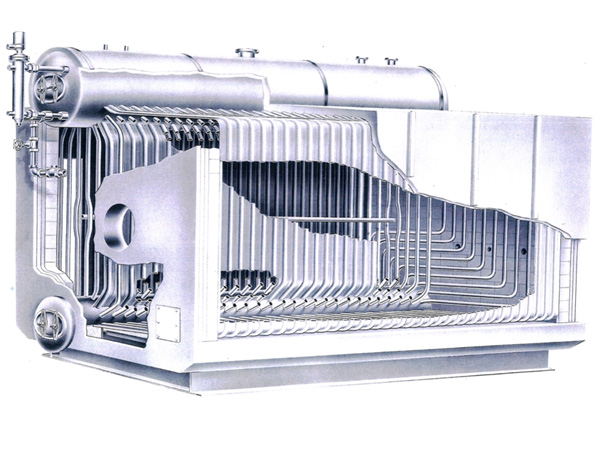

POWERMASTER MODEL WT (WATERTUBE BOILER)

Powermaster WT Packaged Boilers are compact, quality engineered units designed to provide dependability and high operating efficiencies in the production of steam. They are completely shop assembled, including burner, combustion controls, forced draft fan, soot blower (optional), feed and check valves, water column, low water cut-off, boiler blowdown valve and steam gauge and such other optional trim as may be desired.

CAPACITIES: Standard units range from 8,700 to 60,000 lbs. of steam per hour. Special units are available for capacities to 100,000 lbs. per hour. Standard design pressure is 250 psi. Higher design pressures available.

FUELS: Gas, oil or combination gas/oil firing.

SPECIFICATIONS: Construction meets all A.S.M.E. and Military Specification requirements.

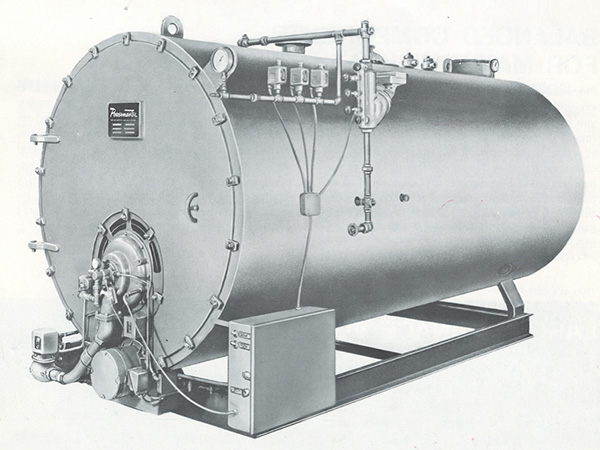

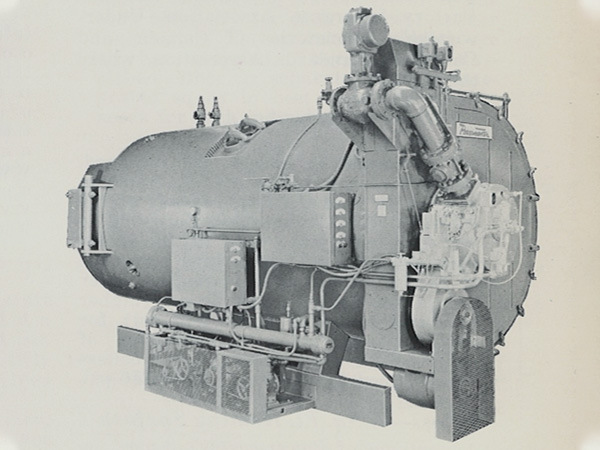

POWERMASTER MODEL PF - Positive Flow

Engineers throughout the world have described the Powermaster Positive Flow® boiler as "the greatest advance in packaged boiler design in seven decades by its unique development of a fire-tube boiler that incorporates the circulation advantages of a water-tube design." Available in oil, gas and combination gas/oil models. Hot water boilers are specifically engineered for modern forced circulation heating applications. Thermal shock stresses are safely absorbed even with momentary loads up to 400% of boiler capacity and maximum temperature differentials of 120ºF.

Features: POSITIVE CIRCULATION design permits boiler feed injection and natural thermal circulation to augment each other. This provides maximum water circulation rate with the most efficient form of heat transfer - counterflow - resulting in uniform metal temperatures throughout boiler during operation. SIDE LOCATED FURNACE eliminates danger of heat damage due to stagnant water and sludge. Turn-around spaces are simple, accessible and positively sealed. HINGED FRONT AND REAR COVERS, with quick-opening fasteners (no bolts). Front can be opened for access to heating surface without disturbing burner, wiring or piping. Design provides exceptional ease of accessibility and maintenance. All these features PLUS: 3-pass design; 5 sq. ft. of heating surface per boiler horsepower; dry back or optional interchangeable wetback construction. For efficiency, burner and control features see listing under model 3.